Description

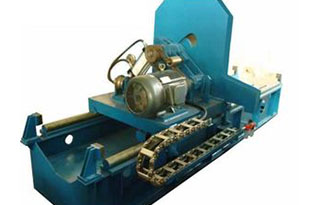

Flying saw serves as the key equipment in the ERW mill and cold rolling mill. It could perform high precision cutting while the pipes and profiles are moving at high speed. It mainly consists of control system, drive system, mechanic body, hydraulic and pneumatic system.

Model for friction saw

| Type | Specification | Thickness | Tube length | Tolerance | Trailing speed | Actuated by | Machine length |

| (mm) | (mm) | (m) | (mm) | (m/min) | |||

| φ50 | φ16-φ63 | 0.8~3.0 | 4-15 | ≤±3 | Max.120 | Pneumatic | 4.4 |

| φ76 | φ32-φ76 | 0.8~3.5 | 4-15 | ≤±3 | Max.80 | Pneumatic | 4.8 |

| φ127 | φ36-φ89 | 1.0~4.0 | 4-15 | ≤±3 | Max.70 | Pneumatic | 4.8 |

| φ140 | φ50-φ114 | 1.0~4.5 | 4-15 | ≤±3 | Max.70 | Pneumatic | 4.8 |

| φ165 | φ60-φ165 | 2.0~6.0 | 4-15 | ≤±3 | Max.60 | Hydraulic | 4.8 |

| φ219 | φ89-φ219 | 2.0~8.0 | 4-15 | ≤±3 | Max.60 | Hydraulic | 4.8 |

| φ273 | φ114-φ273 | 4.0~10.0 | 4-15 | ≤±3 | Max.50 | Hydraulic | 4.8 |

| φ325 | φ165-φ325 | 4.0~12.0 | 4-15 | ≤±3 | Max.40 | Hydraulic | 5.6 |

| φ426 | φ165-φ377 | 6.0~16.0 | 4-15 | ≤±3 | Max.35 | Hydraulic | 6.0 |

| φ508 | φ219-φ406 | 6.0~18.0 | 4-15 | ≤±3 | Max.35 | Hydraulic | 6.0 |

Flying Saw All Digital Control System

- Utilizing the world leading 32-bit module capable of nano-second data processing with

response speed four time faster than the forming module, thus the leap of the control system of cut-off machine from analogue control to digital control realized.

- Latest coding digital processing technology can improve the precision of encoders by over

10 times.

- The whole controller is of compact structure with less electron components. SMA technology

is adopted for all the core components, making the system more aseismatic and totally free from the potential trouble caused by loose connection.

- Various communication ports are available for convenient connection and communication

with the other equipment.