Description

Direct forming mill to square pipe/ Square Welded Tube Machine

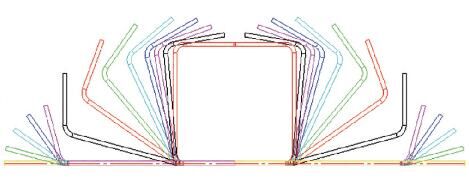

The production of square/rectangular pipes adopts the combined roller.. The roller position will be adjusted by spacer and motor adjustment to realize one set of roller to apply for different size of pipe.

Direct square and rectangular pipe mill feature:

1.Position of roller will be adjusted automatically by motor. And roller can be shared with different size, so time and labor is saved when changing size.

2 Multipoint preflex assembled forming roller design technology, flexible Cold Roll Forming, high quality product, low roller loss.

3. AC motor drives individually, which is higher effective lower energy consumption and maintenance cost.

4. Perfect shape of the tube, the R Angle maintain uniform.

| Model | Square & Rectangle Pipe | Opening Cold Forming

Steel |

Speed (m/min) | ||

| Diameter(mm) | Thickness (mm) | ||||

| LW400 | □100 | 40×40~100×100 | 1.5~5.0 | The Same Specifications | 20~60 |

| LW600 | □150 | 50×50~150×150 | 2.0~6.0 | 10~45 | |

| LW800 | □200 | 80×80~200×200 | 3.0~10.0 | 10~35 | |

| LW1000 | □250 | 100×100~250×250 | 4.0~12.0 | 10~35 | |

| LW1200 | □300 | 150×150~300×300 | 4.0~14.0 | 10~30 | |

| LW1400 | □350 | 200×200~350×350 | 4.0~16.0 | 10~30 | |

| LW1600 | □400 | 250×250~400×400 | 6.0~18.0 | 6~20 | |

| LW2000 | □500 | 300×300~500×500 | 8.0~20.0 | 6~20 | |

Note : The line is non-standard products and can be produced according to user requirements, parameters sheet for reference only.