Description

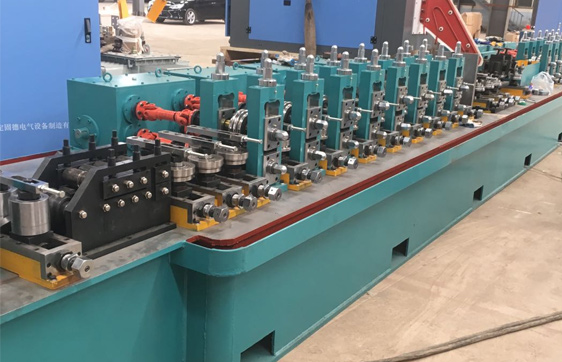

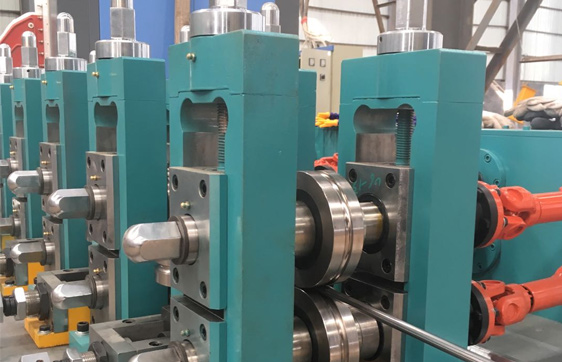

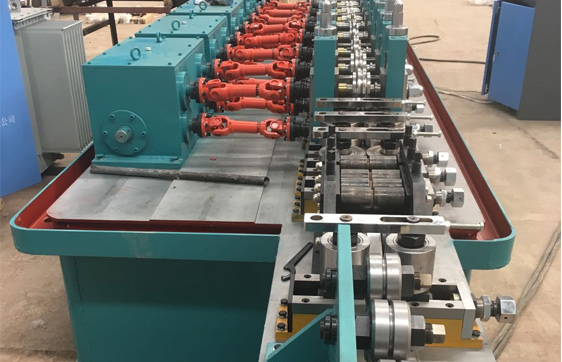

ERW/HF Tube&Pipe Machine

It is designed to roll steel strips to produce continuously to longitudinal welding steel tube, which is used to produce structure round ,square and rectangular tube, profile tube.

Technical Procedures

Coil loading→Uncoiling→Shearing & Welding→Accumulating→Forming→HF welding→Outer de-burring→Seam polishing→water cooling→Fine sizing→Turk straightening→Flying cut off→Run out table→Packaging→storing.

| Model | Round Pipe | Square & Rectangle Pipe | ||

| Diameter(mm) | Thickness(mm) | Diameter(mm) | Thickness(mm) | |

| L-ERW32 | Φ8~Φ32 | 0.4~1.5 | 10×10~25×25 | 0.4~1.0 |

| ERW32 | Φ8~Φ32 | 0.5~2.5 | 10×10~25×25 | 0.5~2.0 |

| L-ERW60 | Φ12~Φ63 | 0.6~2.5 | 15×15~50×50 | 0.6~2.0 |

| ERW60 | Φ12~Φ63 | 0.6~3.0 | 15×15~50×50 | 0.6~2.5 |

| L-ERW76 | Φ21~Φ76 | 0.8~3.5 | 15X15 ~ 60X60 | 0.8~3.0 |

| ERW76 | Φ25~Φ76 | 1.0~4.0 | 20X20 ~60X60 | 1.0~3.5 |

| ERW89 | Φ32~Φ89 | 1.5~4.5 | 25X25 ~70X70 | 1.5~4.0 |

| L-ERW127 | Φ25~Φ127 | 1.0~4.0 | 20X20 ~100X100 | 1.0~3.5 |

| ERW127 | Φ48~Φ127 | 1.5~5.0 | 40×40~100×100 | 1.5~4.5 |

| ERW165 | Φ60~Φ165 | 2.0~6.0 | 50×50~130×130 | 2.0~5.5 |

| ERW 254 | Φ114~Φ254 | 3.0~8.0 | 90×90~200×200 | 3.0~6.0 |

| ERW273 | Φ114~Φ273 | 4.0~10.0 | 90×90~200×200 | 4.0~8.0 |

| ERW325 | Φ165~Φ325 | 4.0~12.0 | 150×150~250×250 | 4.0~10.0 |

| ERW426 | Φ165~Φ426 | 6.0~14.0 | 130×130~300×300 | 6.0~12.0 |

| ERW508 | Φ165~Φ508 | 6.0~16.0 | 130×130~400×400 | 6.0~16.0 |

| ERW630 | Φ325~Φ630 | 6.0~18.0 | 300×300~500×500 | 6.0~18.0 |

Note : The line is non-standard machine and can be produced according to user requirements, parameters sheet for reference only.